During the past fifteen years Intellectual Alliance Inc. (IAI) has focused on researching plasma vacuum technologies and developing applications, based on different carbon forms. IAI has focused on Diamond-Like-Carbon (DLC) carbon nanocoating, including proprietary coating process technologies for metal forming, cutting, plastic processing, oil and gas industry hard and low friction, inert coatings.

Constantly working with carbon-based coatings at the nanometer (10-9 meter) level, IAI researched such physical and chemical production processes as: continuous magnetron and ion beam sputtering, physical and chemical vapor deposition in ultra high vacuum (UHV) conditions, developing methods, algorithms and software to manage pressure, temperature, electrical plasma and other parameters automatically.

Current DLC coating process, which is actually growing amorphous carbon crystal, produces small amount of secondary nanocarbon products that are C60 and C70 Buckyballs and higher fullerenes and trace multiwall carbon nanotubes. To produce commercial volume of these carbon nanoproducts in recent conditions is not feasible, but combination of classic method of production carbon nanoproducts and IAI’s achievements and usage of current methods of growing carbon crystals has options to meet market requirements on commercial volume and quality and cost of carbon nanoproducts.

As such a combination has significant number of choices to apply, to achieve predictable properties of carbon nanoproducts significant researches and experimental development were required to improve classic method of production fullerenes and nanotubes.

Classic Technologies

There are three major approaches to produce fullerenes or carbon nanotubes. These are:

|

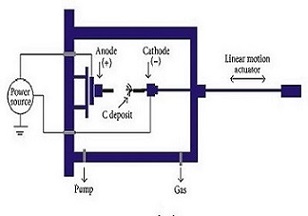

Arc Discharge Method |

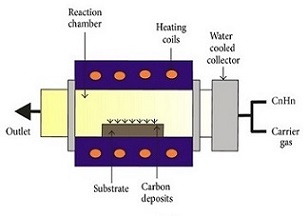

Chemical Vapour Deposition |

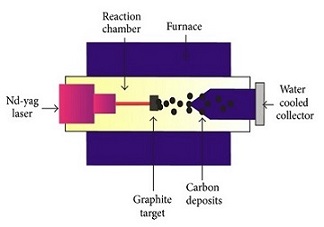

Laser Ablation |

|

|

|

The first option involves a pure graphite arc discharge method to break carbon bonds to synthesize fullerenes or nanotubes while combustion-based CVD synthesis uses carbon inclusive gases to produce fullerenes. Both methods can provide superb nanoproduct purity, but fullerenes provided by gas-sourced carbon are contaminated by oxygen compounds which makes it unsuitable for major IAI’s product applications.

The laser vaporization (ablation) method enables small quantity fullerene or nanotube production for laboratory research.

The prevailing opinion is that the arc discharge method is unscalable; therefore, incapable of commercially viable production. IAI’s technological breakthrough has scaled this method to produce economically viable oxygen-free carbon nanoproducts.

At IAI we designed and developed unique arc discharging vacuum system for 48 hours continuous production of the highest quality carbon nanoproducts, fullerenes or nanotubes in commercial volume.